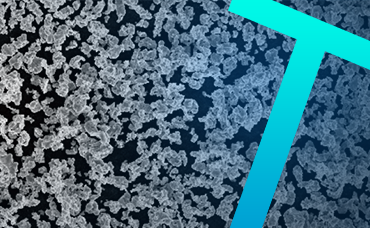

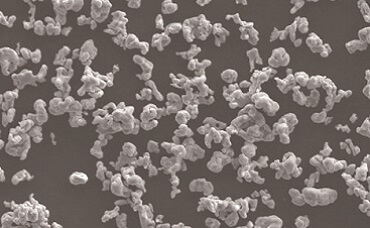

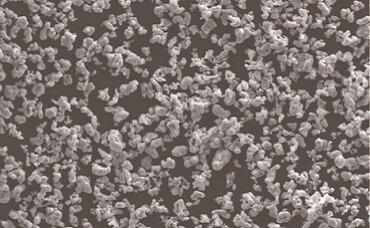

Superfine Iron Powder

Nearly 20 years of research, development and production experience in micron scale iron powder technology. Specialized in particle size control in large scale production of iron powder with particle size in the range of 0.5 to 20μm.

Since its inception, SAGWELL has been focusing on the exploration of superfine metal powders, developing its own proprietary know-how, and pioneering in novel chemical technologies to make micron scale metal powders.

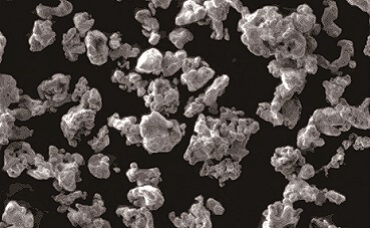

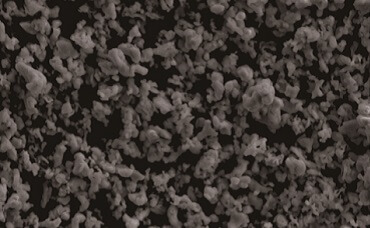

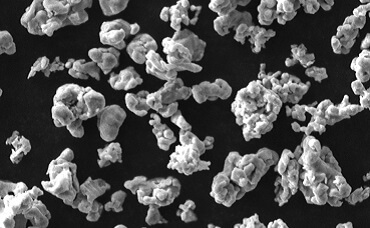

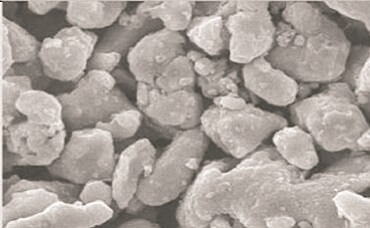

Characteristics

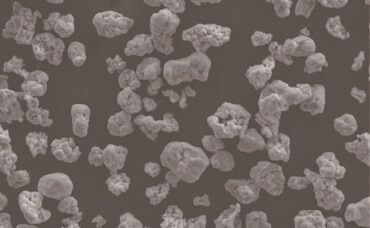

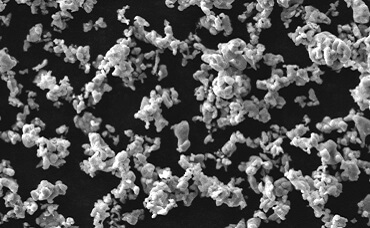

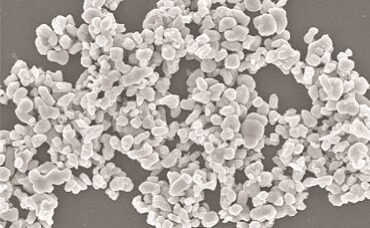

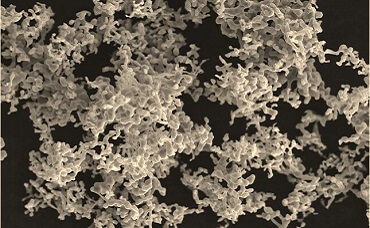

0.5-20 μm similar like spherical particles

0.5-20 μm similar like spherical particles Excellent compaction & sintering properties

Excellent compaction & sintering properties High purity iron powders

High purity iron powders Stable batch production

Stable batch production High activity iron powders

High activity iron powders High permeability & low eddy current loss

High permeability & low eddy current loss

Iron Powder Series

Here only shows our regular products, feel free to contact us for more product information.

Data

| Grade | Fe(%) | O(%) | C(%) | N(%) | P(%) | D50(μm) | Mesh |

|---|---|---|---|---|---|---|---|

| EHA-T | ≥98.8 | ≤0.50 | ≤0.03 | ≤0.01 | - | 4.0-8.0 | 3000 |

| UHA | ≥98.8 | ≤0.60 | ≤0.03 | ≤0.01 | - | 4.8-5.5 | 3000 |

| UHB | ≥98.5 | ≤0.85 | ≤0.03 | ≤0.01 | - | 3.3-4.3 | 4000 |

| UHD | ≥98.85 | ≤0.70 | ≤0.03 | ≤0.01 | - | 7.0-9.0 | 1500 |

| UHF | ≥98.2 | ≤1.15 | ≤0.03 | ≤0.01 | - | 2.5-3.5 | 5000 |

| UHF-P | ≥96.65 | ≤1.04 | ≤0.01 | - | 2.0-2.3 | 2.2-3.2 | 5000 |

| UIF | ≥98.55 | ≤0.80 | ≤0.03 | ≤0.01 | - | 2.55 | 6000 |

| UI-100 | ≥98.0 | ≤0.80 | ≤0.015 | ≤0.01 | - | 43.0 | 350 |

| ZB | ≥98.3 | ≤1.10 | - | - | - | 3.0-4.8 | 3000 |

| ZF | ≥98.2 | ≤1.15 | - | - | - | 2.5-3.5 | 5000 |

| SE-02 | ≥98.5 | ≤0.66 | - | - | - | 47.0-48.4 | 300 |

| SR-B | 94.0 | ≤3.0 | ≤2.0 | ≤0.01 | - | 2.5-3.5 | 5000 |

| TUA-1 | Backing powder of laser welding | 4.7-5.7 | 3000 | ||||

| TUF | Special material for free sintering | 3.2-4.2 | 4000 | ||||

Have some questions?

How can I get the datasheet or know the price?

Please send email to [email protected] or go to the contact us page and you'll find a feedback form.

Can we get technical advice?

Of course yes. SAGWELL has more than 20 years experience in micro & nano metal powder materials, our technical team are ready to answer any questions you have.

If you are not sure which product is the best for you, we'll recommend the corresponding products for your needs.

Can I get a sample for testing?

Yes, we offer free small sample for testing, feel free to contact us.