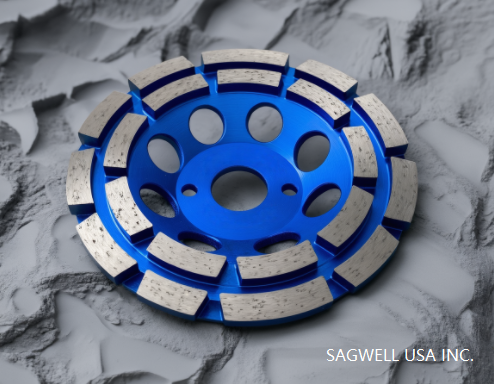

Recently, a client needs to bid for a 30,000-square-meter C35 concrete high-precision floor grinding project, which must be completed within 20 days. He contacted the technical team of Sagwell to inquire about what ultra-fine iron powder can improve the sharpness of the grinding pads.

Analysis of Project Difficulties

The project requires the floor to achieve a strict flatness standard of less than 8mm deviation per 2m after grinding, and all work must be completed within a 20-day schedule. This imposes extremely high requirements on the cutting efficiency and durability of the grinding tools. If the client uses the original grinding pads, they will face dual challenges of tight schedule and high costs.

Technical Solution: Optimizing the Matrix Material with Ultra-fine Iron Powder S2386

After analyzing the client's existing floor grinding pad formula, Sagwell's technicians found that although the 30/40 mesh diamond abrasive has sufficient hardness, the chip removal performance and self-sharpness of the traditional matrix material (composed of iron, copper, tin, etc.) can be optimized. Through comparative tests in the material laboratory, it was proposed to partially replace the ordinary ultra-fine iron powder in the original matrix formula with ultra-fine iron powder S2386 . This iron powder can significantly enhance the brittleness of the matrix, thereby improving sharpness.

The optimized grinding pads showed remarkable performance improvements in the client's tests:

Under the working conditions of a 12-head planetary grinder (22kW power, 280rpm speed), the single-machine hourly grinding efficiency reached 40 square meters, an increase of about 18% compared to the original formula.

Cost Control: Although the unit price of S2386 iron powder is about 5% higher than that of ordinary ultra-fine iron powder, it only needs to replace 15-20% of the original formula, so the overall matrix material cost increase is controlled within 1%. Considering the savings in equipment shift fees(It is expected to reduce the input of 3 sets of equipment) and optimized labor costs, the overall project cost can be reduced by about 5-7%.

Durability: In the 72-hour continuous working condition test, the new floor grinding pads had an average service life of 35 hours, with a wear rate 10% lower than the original product, fully meeting the construction intensity requirement of 1,500 square meters per day.

ultra-fine iron powder can enhance the sharpness of diamond tools, an effect that ordinary iron powder cannot achieve. Sagwell welcomes more exchanges on this topic.

Please feel free to consult for more details.

Email: [email protected]