What kind of alloy powder is effective for enhancing the impact resistance of diamond tools? To create a tool matrix with strong impact resistance, a key requirement is balancing two core properties: the matrix must retain sufficient toughness, while its ability to hold (or retain) diamonds does not become overly weak.

Recently, technical experts from Sagwell shared a typical customer case that illustrates this principle.

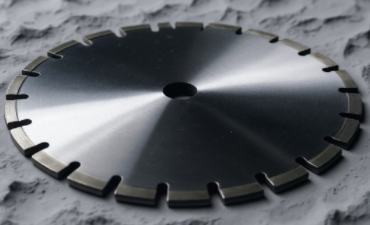

The customer in question used small diamond saw blades to cut high-hardness ceramic tiles. During the cutting process, the instantaneous impact force generated was quite substantial. As soon as the saw blade came into contact with the tile surface, intense sparking occurred—so severe that the saw blade was vividly described as a "fire wheel," a term that captures the extreme intensity of the sparks. Concerned about this issue, the customer sent the problematic saw blade to Sagwell, seeking to identify the root cause of the failure.

Sagwell’s technicians conducted a detailed inspection: they examined the saw blade’s working surface under a microscope and made critical observations. Multiple fracture pits were found on the matrix, and even the pockets (the small recesses designed to hold diamond grits) had developed holes. Notably, the customer’s initial choice of an alloy powder-based matrix for the small saw blade was not incorrect. After in-depth communication with the customer, Sagwell proposed a targeted solution: adjusting the matrix to enhance its impact toughness. Specifically, this involved moderately increasing the matrix’s toughness and strength, which would in turn strengthen its diamond-holding force—ultimately improving the matrix’s overall impact resistance.

This matrix adjustment strategy is not limited to small saw blades; it can be applied to a wide range of diamond tools. For practical implementation, Sagwell’s technicians recommend using conventional iron-copper-nickel alloy powder as the base material. From there, the balance between the matrix’s toughness and brittleness can be fine-tuned based on the specific type of workpiece (i.e., the material being processed).

Please feel free to consult for more details.

Email: [email protected]