For Diamond Tools

Sagwell supplies all types of metal powders to the diamond tool industry (iron, copper and pre-alloyed powder), we have the most comprehensive product range for diamond tool industry.

Sagwell powder's sintering organization is similar to cobalt powder, the matrix is evenly sintered, fine and compact. With strong coated degree and holding force, it is suitable for middle and high grade tools.

Superfine Iron Powder

The ultra-fine iron powders under micro-scale series made by chemical method are fine powder particles (particle size between 3~10um) and have homogeneous particle size, low oxygen content and high purity. It can significantly reduce the sintering temperature and can be alloyed in the temperature range of 700~900 °C.

The homogeneous, exquisite matrix, and high densification (>98%) of the organization are good for the holding force to diamond so as to improve the utilization rate of diamond.

In the adaptive temperature range, the sintered matrix has good structural homogeneity and density whilst the sintering hardness is 85~100 HRB and the bending strength is over 1000 MPa., which can effectively improve diamond protrusion.

The outstanding features are the comprehensive mechanical performance and being capable of wide application, which is suitable for making high-grade granite cutting & grinding tools, saw blades, engineering drill bit, and ceramic cutting & grinding tools, etc.

Superfine Copper Powder

Made in chemical method, our superfine copper powder is spherical or nearly spherical. Single particle under scanning electron microscopy (SEM) shows that the powder is porous and it has got high purity, apparent and tap density, and low impurity content, which is suitable for making high-grade diamond tools.

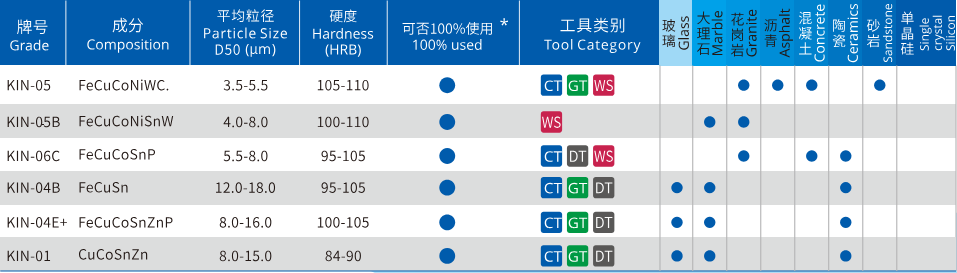

Superfine Pre-alloyed Powder

Made by chemical method, our superfine pre-alloyed powder is low oxidation, has near-spherical particle shape, homogeneous particle composition and excellent compaction & sintering properties. Beyond that, we ensure stable & repetitive batch production.

Medium and High Grade Pre-Alloyed Powder

Our medium and high grade pre-alloyed materials have superfine micro-nano lattice morphology, fast sintering reaction speed, exquisite sintering structure and strong mechanical properties, which can meet the better basic needs of the matrix and improve the overall quality of the tool.

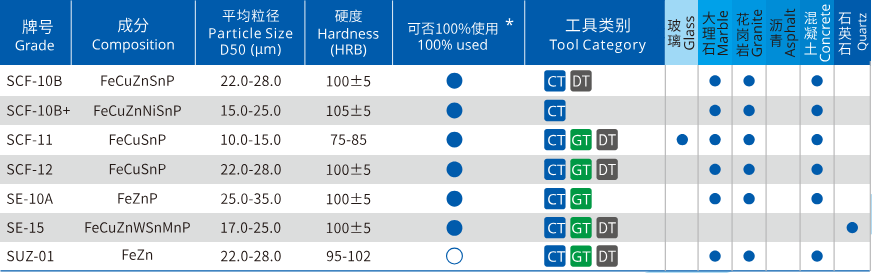

Green and Eco-Friendly Pre-Alloyed Powder

As the low-cost, high-efficiency green and environmental friendly material, we have adopted an advanced and environmental friendly production process to produce pre-alloyed powder with the micro-nano lattice morphology originally, which has the characteristics of fast diffusion speed and high sintering density.

Meanwhile, considering the process characteristics of improving the cold press molding and the flow of powder without using granulation process, we have agglomerated the original particles to make the average particle size of powder particles reach 20-45 microns, and it also takes into account the excellent mechanical properties of the original micron powder. The powder can be used as 100% formula powder. (Such kind of pre-alloyed powder does not need to be granulated)

Other Pre-Alloyed Powder

The reinforced and improved pre-alloyed powder has the characteristics of superfine micro-nano particle size, fast sintering diffusion speed and higher reinforcement, which can effectively improve some the characteristics of the matrix formula in some aspect, such as self-sharpening, toughness, wear resistance, and temperature reduction.